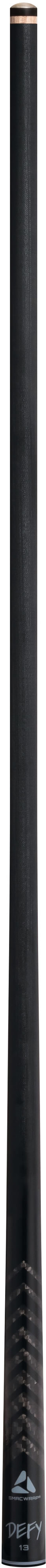

McDermott Defy Carbon Fiber BREAK Shaft - Uniloc Joint |

McDermott Defy Carbon Fiber BREAK Shaft - Uniloc Joint

NEW & IMPROVED

Our newly-engineered Defy shaft has a

brand new finish that allows it to glide through your hands more

smoothly than ever before!

It also features a new ferrule material for enhanced durability.

DEFY HIGH-PERFORMANCE CARBON FIBER SHAFT

Introducing Defy — a shaft that defies

the stereotype of carbon fiber shafts.

Defy gives you the

unparalleled accuracy and control that you expect from carbon fiber,

but uses state-of-the-art technologies to shatter its limitations.

SmacWrap, originally designed for the aerospace industry, absorbs

vibration and dampens noise resulting in a confident hit with a soft

feel and quiet sound. Our super-smooth coating reduces friction,

allowing the shaft to glide through your fingers with ease like a

wood shaft. Only Defy’s insane energy transfer and accuracy will

remind you that you’re using a carbon fiber shaft. Patent:

11,534,676

NAVIGATOR Break Impact

The Navigator Break Impact is

a hybrid phenolic break tip. Most phenolic tips are designed

to generate power, but at the cost of cue ball control. The

Break Impact tip’s hybrid construction provides tremendous

cue ball control without sacrificing power. This makes it

ideal for breaking and jump shots.

Standard Specifications:

Tip: Navigator Break Impact (Ultra Hard)

Ferrule Color: Phenolic

Shaft: 13mm Break Taper

Joint Diameter: .843" (Standard for Uniloc and Radial Pin)

Length: 29"

Warranty: Limited Lifetime

|

Standard Viking Order Form

Question: I would like to purchase a Defy shaft

but I do not know what is the right joint diameter for my cue.

Do I need the .843" or the .855" joint diameter?

Answer: Our joint diameter can vary from cue to

cue due to our finishing methods, so it would be best to

physically measure the joint diameter with a caliper. Most steel

collar joints will be close to the .843", while many non-steel

McDermott joints may be closer to the .855" diameter.

Cleaning Instructions:

Defy carbon fiber shafts have a special finish that contains a

slip agent. This helps keep the shaft slick and resists chalk,

dirt, and hand oils from soiling the shaft. For peak

performance, you may periodically clean the shaft by wiping it

down with an alcohol wipe.

Never sand the surface as this will damage the special finish

and void the lifetime warranty. Do not use talcum powder, baby

powder, hand chalk, or any solid or liquid abrasives.

|